Raw Material Processing

Mild steel scrap received first segregated and stored in our scrap yard.Various grades of MS Scrap are supplied from the yard to the furnace as per requirement. Various Scarps are handled by grab/magnet fitted with overhead Electric crane and charged into an Induction furnace.

Melting Process

Melting Process melt various grades of Scrap and Sponge Iron into liquid metal upto 1650 centigrade temperature. During the entire process of melting,impurities are taped off and chemistry is checked regularly in our in house laboratory for the right quality. Once the required chemistry and temperature is achieved liquid metal is transferred to the Ladle furnace.

Ladle Purging Process

Liquid metal transferred to ladle is added with ferro chrome alloys and purged with inert gas to complete the secondary steel making process.Ladle is later moved to the continuous casting machine and placed over a tundish car.

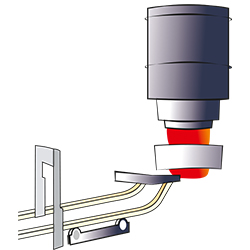

Continuous Casting Process

Slide gate assembly at the bottom of the ladle is opened hydraulically and poured into the tundish and oscillation table maintains optimals oscillation speed in order to guide the liquid metal into a casted Billet and poured into tundish( into the mould tube. Mould tube) oscillation table.

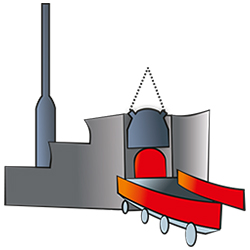

Hot Charging

Casted Billets are cut manually to a right size and they are fed directly to the rolling mill as hot Billet. Hot Billets are maintained at right temperature and size as they travel through the platform.

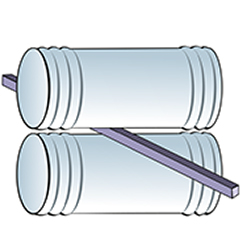

Rolling Process

Billets for conversion into TMT travels in the Roller conveyor (130 Meter Long) and passes through Roughing Mill, Intermediate Mill and converted into TMT Bars of required dimensions.

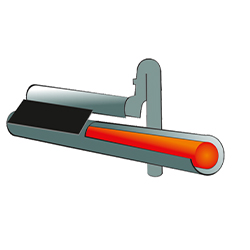

Quenching Process

.jpg)

Quenching Box cools down the TMT Bar by pouring Pure water at high pressure through controlled valves and nozzles to get the desired Mechanical properties of the Bars.

Bundling & Storage Process

.jpg)

Shearing operation is to achieve the correct length.

Dispatch Process

Shearing operation is to achieve the correct length.